Is 0 0 A Solution

Among the many effects of the supply concatenation problems in the summer of 2022, aviation discovered that it was having a difficult time operation without a elementary article—the oil filter. Lycoming and Continental engines everywhere needed spin-on, dispensable oil filters to keep flying, and the supply was extremely limited. KITPLANES research found that Champion had finer stopped product—though information technology is at present ramping support—while Tempest was going at their normal production rate and trying mightily to increment it to see demand. Merely Tempest simply couldn't double its production overnight, so suppliers' shelves emptied as aircraft owners quickly bought up every filter they could find. Remember the toilet paper shortages in the early days of COVID? Yeah, it was sort of like that.

Homebuilders searched their favorite forums to meet if anyone had an extra filter on the shelf when it came time for an oil modify, and as a hopeful sign of civility, many filters changed hands so that pilots could go on to wing. Some oil-change intervals might have been fudged—but for personal Function 91 operations, nothing says that you tin can't become an actress 10 hours if you choose to do so. Not so lucky were flight school and rental-fleet operators, many of whom discovered that they had to find filters—at any cost—or stop operating some (or all) of their aircraft when inspections and oil changes came due. Lack of a $xl oil filter turned into much lost revenue.

Fortunately, at that place is—and has been for many years—an option to spin-on disposable filters. And no, I am not talking near going back to the elementary oil screens that engine manufacturers used for over one-half a century before disposables came along. The original screens (I had a couple on my early airplanes) were insufficiently very coarse, which meant they needed to be cleaned and the oil changed every 25 hours, according to Lycoming. Spin-on filters allowed intervals to be stretched to l hours—a welcome cost savings for aircraft owners, both certified and Experimental. Spin-on filters had, of grade, been used in automobiles for a century—but took a fiddling longer to make their manner into aviation. Now, of course, they are pretty much the de facto standard. But an culling is the permanent, cleanable filter that attaches to the same adapter equally a disposable, spin-on filter.

Pioneered in general aviation by Challenger Aviation, the permanent filter has economic advantages in the long run (it will pay for itself afterwards a certain number of oil changes) and reduces waste product. And based on testing performed by G&P, which manufactures the filters for Challenger, it appears to provide better filtration and higher oil flow rates—both of which should be better for your engine.

How Good?

There are two parameters used to measure the "quality" of oil filters—particle size (how fine the filter is) and flow rate. Intuitively, it is obvious that the smaller yous make the holes in the filter media, the smaller components information technology'll catch and the cleaner your oil will exist. Media is rated by hole size, in microns. The smaller the number, the better the filtration. Still, in that location is a point of diminishing returns because the smaller the hole size, the harder it is to force enough oil flow through the filter chemical element. This is obvious if you reduce the hole size to nil—in this instance, nothing is going to go through!

Thou&P discusses this in particular on their website, citing that paper filters, which they had tested, range from 48 microns to 300 microns. (Behave in mind the source of this information, which is probable to not be impartial.) The variability is simply because no ii paper filters are ever going to exist alike—even when they come off the same manufacturing line. So paper media is rated on averages. But stainless-steel textile is manufactured with a uniform process producing uniform results. The K&P media is rated at 35 microns, for case. Tempest states on their website that their paper filters are rated at 40 microns—which is quite proficient. Challenger told the states that their filters are manufactured to their specifications (by Thousand&P) with a screen rating of 22 microns. In all cases, Thousand&P's testing showed pregnant increase in flow rates over paper filters.

The real question, of course, is "what is good enough?" The respond to this elementary question is elusive. Lycoming has no specifications that place a maximum micron size or menstruum rate, leaving u.s.a. to presume that any filter y'all can buy is sufficient. One maintenance manual we plant for a pop Lycoming clone specified a filter size of 20 microns—and none of the existing filter manufacturers claim to be that good. In truth, we have heard of essentially no engine failures or early overhauls due purely to the fact that the filter wasn't taking care of fine enough materials. Sure, there are engines that were making metal that required early overhaul—but that would have been true regardless of the filter beingness used.

There probably isn't enough information to testify that the permanent filter will provide longer time betwixt overhauls or lower the risk of oil-related engine failures (an astronomically small number unless you count "lack of oil" incidents). Or that it'south any worse than a spin-on. Only if you believe that oil filtration is a skillful affair—and that meliorate filtration is a better matter—then it is hard to argue that the permanent filters, if they do indeed provide equivalent filtering to our well-known paper filters, aren't a reasonable solution to our current supply issues.

In truth, this is actually but a summit-line discussion of filter ratings and capabilities. The subject could be considered a gator-infested swamp, but nosotros're willing to ford into the marsh—that's why we're working on a more in-depth expect at what the ratings mean, how filters are tested and what this may (or may not) hateful for your bodily aeroplane engine. Look for that in a near-hereafter result.

Filter Features

Back to the nuts and bolts. Oil filters are not merely a tin can with filter media inside. There are certain features, which are important, especially for an expensive motor that is keeping you in the air! Yes, you need a good filter media, one that has a good flow rate, and too a small filtration size. Simply what happens if the filter media gets clogged? You notwithstanding demand oil going to the engine's vital parts, so any acceptable filter needs to have a built-in featherbed valve to allow oil continue to flow. Yes, many oil filter adapters on engines have their own bypass valves—simply some of us like a belt-and-suspenders approach, and all good filters accept a bypass anyhow. It's important to know that you don't want to lower the featherbed pressure of course—otherwise, the valve stays open and you lot become no filtration at all.

the X-shaped O-ring lightly with clean

oil earlier installation.

Another feature y'all may or may not detect in an oil filter is an anti-drainback valve. This is commonly a prophylactic flapper that keeps oil in the filter afterward the engine stops and so that when the engine is restarted, the filter is already total and you get firsthand pressure. The demand for this valve is hotly debated by many mechanics, builders and pilots, but the fact that some filters take them and others don't begs the question of whether or not they are essential. In general, Lycoming engines with straight-back oil filters don't use the anti-drainback valve, while those with an angle adapter do. The permanent filters we accept looked at exercise non have them, and nosotros know many owners using the permanent filters on angle adapters with no trouble. We establish no hard evidence on their need ane mode or another.

Other features of aviation oil filters are external, including a large (commonly 1-inch) hex nut on the stop to aid you torque them without a strap wrench, and holes with which to safety wire the filter to the engine. Aircraft oil filters are safety wired because they have always been safety wired—or so it seems. This is another affair hotly debated on homebuilder forums, and this author falls on the side of, "If there is a hole why not safety wire it? And if at that place isn't a hole, there is ane on the engine—and then why not take or brand a provision on the filter?" The Challenger aviation filters accept both the nut and the safety wire holes. The Thou&P filters marketed to the automotive and motorcycle world more often than not exercise not have either—simply it is very easy to add holes in the superlative-about cooling fin, and these units come with a special "cup wrench" that mates to a 3/eight-inch socket bulldoze to make installation easy. Merely don't lose the cup, or you'll be using a strap wrench.

One additional characteristic on the K&P-manufactured filter elements is a small high-force magnet designed to pick up ferrous chunks from the oil. Magnetic drain plugs accept been a thing for years—this is just a variation on the theme and probably not a bad idea, especially if you take reason to believe your engine might be shedding bits of steel or iron.

Permanents

The merely permanent filter intended specifically for aviation employ is the ane designed and marketed by Challenger. Challenger does non currently sell direct to consumers, simply rather through a dealer network, probably the largest dealer being Shipping Spruce. Because of the shortage of disposable filters in 2022, Challenger told us that they were having a difficult fourth dimension keeping upwards with demand, simply were doing what they could to increase their output.

In the same fashion that many home-builders accept used automotive filters on their Lycomings for years, many homebuilders accept been purchasing the K&P-branded filters from various sources. The fact that K&P makes the Challenger filters has been used by many to assert equivalency, only every bit noted a little ways back, the filter element in the Challengers has a finer filigree than the stock One thousand&P product, which partly explains the cost divergence. It as well should be noted that there have been a number of reports from homebuilders who had their orders canceled when Thousand&P found out that the filters were going to be used on aircraft. Some manufacturers are funny that way—which is why, when you lot get to AutoZone to buy a Denso alternator, you must weave the story that information technology is for your beloved '98 Suzuki Samurai and not your homebuilt plane.

When it comes to commerce, some builders will seek out the cheapest solution and some volition decide it'south more than important to back up two aviation companies (Challenger and the benefactor/retailer) for what amounts to a difference equivalent to 20 gallons of avgas. That said, if y'all desire the K&P, you lot'll need the S15, which is a 48108 equivalent correct off the shelf. To supercede a 48110, you'll also need a ¾-sixteen nipple for nigh $8.

Installation Matters

Installing the permanent filters is simple: Spin off the old filter and spin on the new 1. Torque to the spec that comes with the filter, using the hex nut on the end or the cup tool, and safety wire. If you need to add the safety wire holes, information technology'southward simple to drill a #50 hole in the outermost cooling fin. We drilled four in ours, just to requite u.s.a. diverse clockings. Note that the permanent filters come with an Ten-shaped O-ring. The K&P units we received came with a spare—we have read reports of folks using them up to 10 times, and also those who supervene upon them every other oil change. Do what you experience comfy with.

So what do the engine manufacturers and/or the FAA say about the permanent oil filters? Let's start with the FAA. They have issued an STC for the Challenger filter, then they tin can be installed on virtually whatsoever aircraft with a Lycoming or Continental engine. Not that we need an STC in the Experimental world, of course. But clearly Challenger has proven to the FAA that their filters practise the task up to acceptable standards.

As for the engine manufacturers, they are pretty much silent on the topic—equally they are on whatsoever filter choices. We could notice no reference in the Lycoming documentation regarding minimum specifications for oil filters. Continental documentation is also very thin, with only one reference we found in the IO-370 manual that specified a filter with "20 micron filtering," which is problematic, since we couldn't find any filters in the manufacture that meets this spec. The truth seems to be that just as the disposable filters do a good job at filtering oil, the experience of many builders is that the permanents are doing just too.

In a word with Linda Rocco, president of Challenger, we asked about the length of time betwixt oil changes. Lycoming for years recommended a 25-hr oil change/screen cleaning with the quondam screens—but with a total-flow disposable, that could be stretched to l (what almost owners use these days). Rocco said that while they tin can't speak for Lycoming, their position is that pilots should use whatever interval they have been using with disposables when they switch to the Challenger.

Given that the 1000&P filters are specified at 35 microns, and the paper filters are rated at 40, it is probably safe to assume that staying with the fifty-hour number is probably OK—but everyone should decide for themselves.

Just More Bling?

In that location is no doubtfulness that the reusable filters await bully on an engine—smaller, finned, billet-machined…they simply scream "hot-rodding," and that is hard to resist. Just at the same time, they announced to exist a very expert filtration system that takes you out of the dependence of disposable filter availability. Do they actually make oil changes quicker and easier? Well, that depends on if you always go to the attempt to cut open and evaluate your disposable filters. We all should, but many don't. Very few people cut open their car's oil filter to examine the contents, which is why the disposables are quick and piece of cake to use. If yous are just spinning information technology off and throwing it in the trash, so the reusable filter is going to add together to your oil modify time because you pull it off, clean information technology and reinstall—and that takes a little time.

Does the reusable make less mess? Partly that depends on how much mess you brand with your disposable, and that depends on your engine configuration. And at present you demand a container in which to rinse and wash the filter element—simply like we grumbled nigh in the bad quondam days of oil screens. Vi of one, half a dozen of the other—information technology's upwards to everyone to decide what makes the most sense. Nosotros're putting them on our "armada"—and will report back on the results—merely to come up with meaningful results, that might take a couple of years. Counterbalance the pros and cons for yourself—this is, later all, Experimental aviation!

Old Schoolhouse

How practise mod oil filters (either disposable, paper-based or reusable) compare to what Lycoming used originally? Well, way back "in the day," Lycoming engines came with oil screens—not filters. These screens were mounted in housings on the dorsum of the accessory instance, right where spin-on adapters reside now. The screen was cylindrical, with an outer coarse mesh supporting an inner fine screen. Equally with modern filters, the oil traveled through the media, trapping any particles that could do damage. Just how big did those particles have to be in order to become trapped?

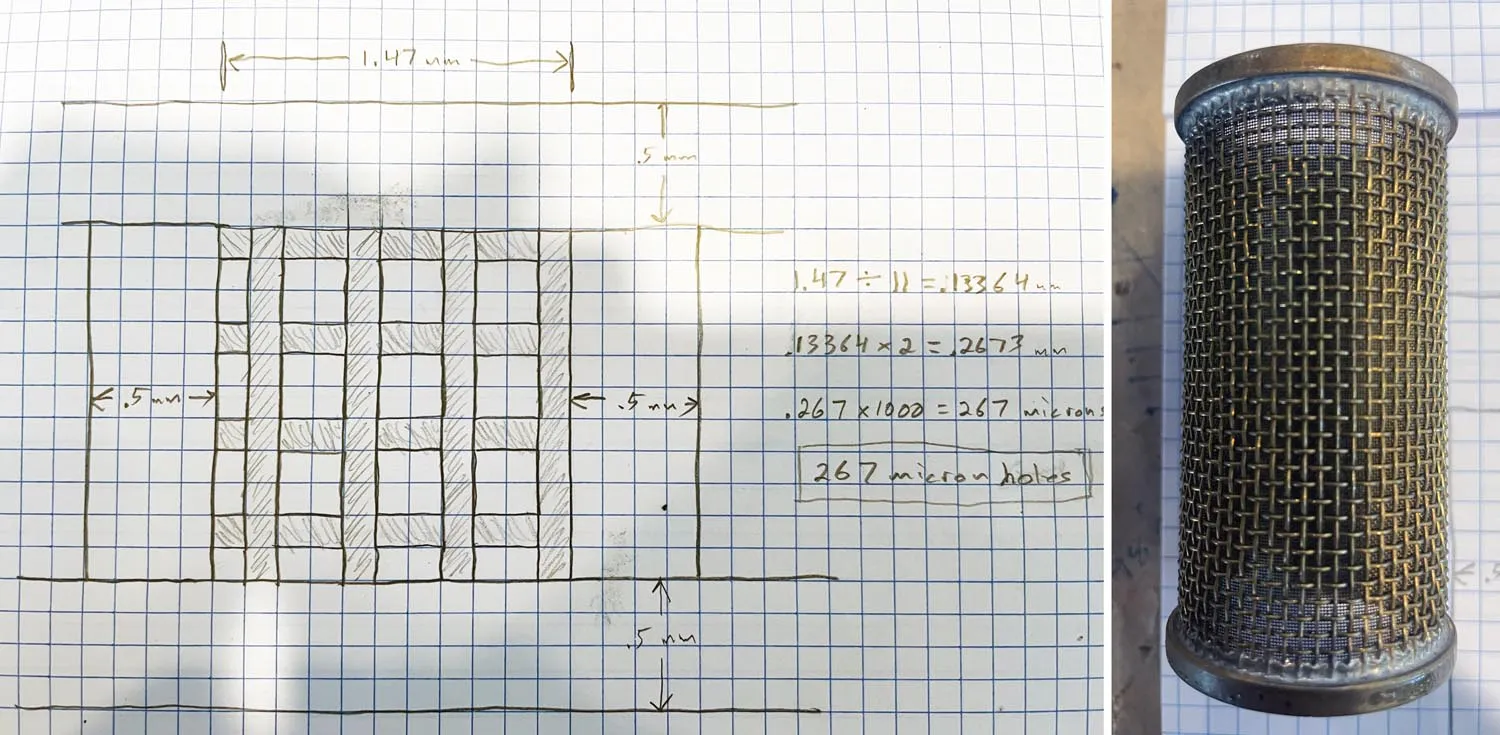

We scrounged up an former screen, and defective a lab in which nosotros could laissez passer measured-sized particles, we did a little measuring and assay.

Looking closely at the screen with a magnifier, nosotros noted that the inner screen repeated a petty more than iv times inside each square of the outer grid. Nosotros measured the outer grid with a micrometer and found that the individual wires were an even 0.five mm thick. The openings in the grids were just under ane.5mm. We measured ten examples and averaged them to get 1.47mm. The inner screen appeared to have squares nearly twice the size of the wires in the screen, and counting "wire widths," we came up with 11 "units" with each square two "units'' wide. So, one.47 divided past 11, times two, gave us the screen opening sizes of 0.267mm. Converting that to microns (i-one-thousandth of a millimeter), we came upwards with a screen size of 267. Bookkeeping for measurement error and variability, let's say that the screen is somewhere between 250 and 280 microns.

Now, 250 microns is a far cry from the 22-micron Challenger filter, the 35-micron K&P or the quotes we become for paper filters from 25 to 100 microns. Whatever of these filters does a far better job at filtering particles from your Lycoming than the former screen did. Do you suppose that has something to do with the fact that engines used to accept much shorter TBOs and often didn't attain those times? We'd dearest to see the data—only I don't call back information technology exists. The bottom line? We were OK with screens, but we're very happy with whatsoever of the modernistic filter options!

What the Manufacturers Say

Since KITPLANES doesn't really accept the budget to set upwards a laboratory examination for period rate and filtration of a wide variety of oil filters, we have to rely on what the manufacturers say about their products. In researching the reusable oil filters, we found these tidbits from websites, conversations and emails.

Challenger Aviation filters are made past Yard&P to Challenger's specifications, which include a 22 micron filter size. Challenger besides specifies housings with the i-inch hex nut on the end, which includes holes for safety wire.

Thousand&P says this on their website about the comparison of their filters to paper filters:

We use ASTMF316 testing procedures which eliminate many of the user variables plant in the SAE procedures. Basically, the filter media is pressurized from ane side, and when the media starts passing particles, that is the micron rating. We sent filter media from several common brands of paper filters to the lab to be run through the ASTM test. We sent the media to the lab with no names, merely numbers for identification so they wouldn't accept any idea what make filter they were testing. The results for the paper filters ranged from 48 microns for the all-time filter to over 300 microns for the worst filter. Our tests were correct in line with other testing results we have researched that have newspaper media filters passing particles anywhere between 50 and ninety microns. What does this mean? Paper filters are rated on averages, percentages of efficiency (also known every bit beta ratios) and multiple passes, so a 10 micron rated newspaper filter (as advertised on the packaging) may be letting particles 50 microns and larger through. The medical course stainless steel cloth that we use is consistent beyond the entire media surface and is rated at 35 microns, significant nada larger than 35 microns should pass through the material. The lesser line is we meet or exceed the filtration performance of OEM filters, eliminating any warranty problems.

Alan Woods, of Champion Aerospace, gave the states this response when we asked how they rate their high-finish paper filters:

The respond to your question is not completely straightforward. To start with, the Champion line of aviation filters is the only certified aviation filter that meets or exceeds the ARP1400B standard for filtration. Our filters are rated at 25 microns with a filter efficiency of 75% and xl microns with a filter efficiency of 90%.

And Storm, on their website, says this about their micron rating:

Q: What micron rating is your oil filter?

A: Tempest oil filters use media with a 40-micron rating.

Every bit for the actual requirements for oil filters specified by engine manufacturers, we could find no reference in the Lycoming Service Bulletins or Continental documentation.

This article originally appeared KITPLANES. For more than cracking content like this, subscribe to KITPLANES!

Is 0 0 A Solution,

Source: https://www.avweb.com/ownership/a-permanent-solution/

Posted by: edwardsushe1984.blogspot.com

0 Response to "Is 0 0 A Solution"

Post a Comment